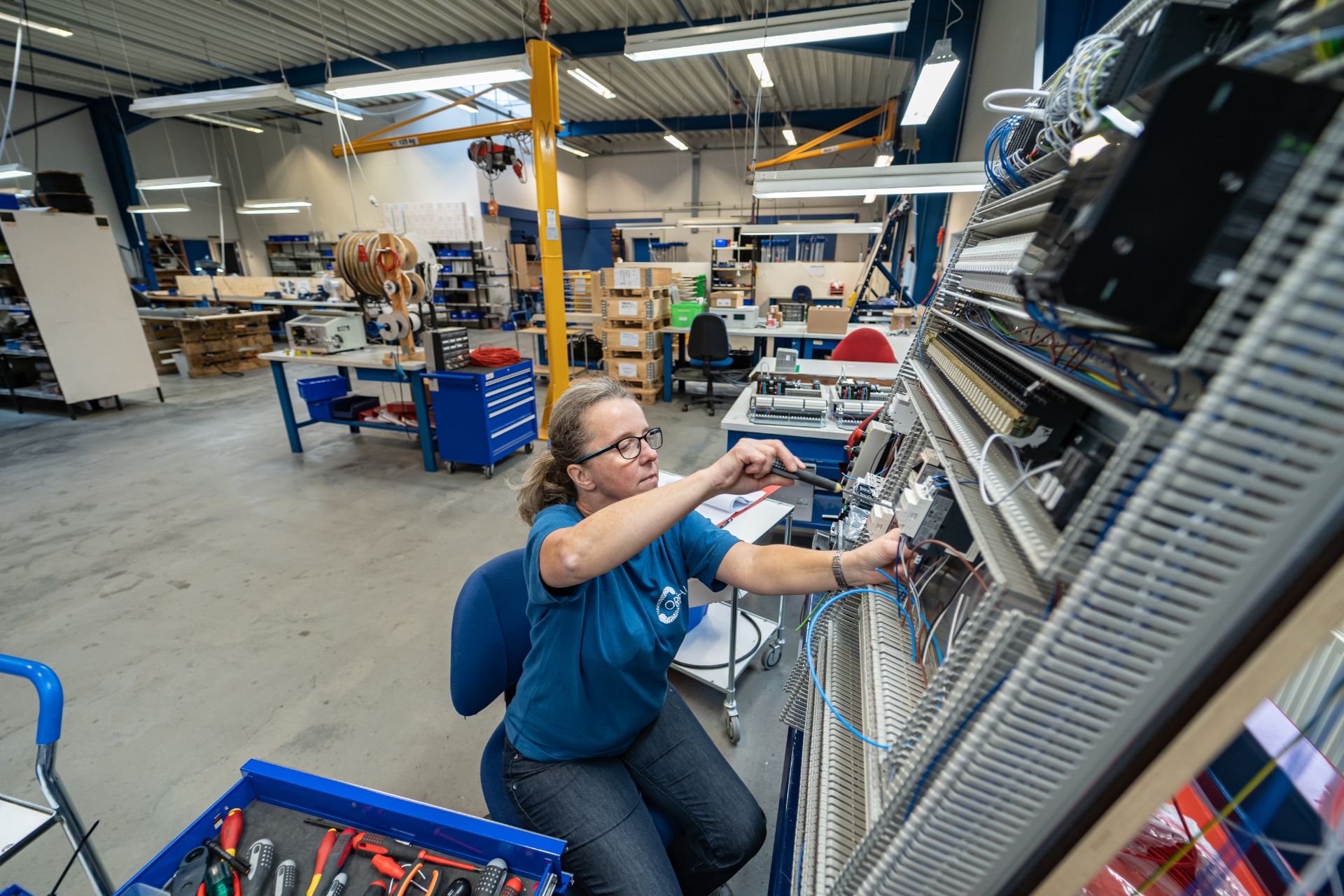

Control boards

Competitive board production in DK-6900 Skjern

Do not pay for more than you need. The board production in Skjern builds your boards efficiently, carefully and delivers on time. We have streamlined production processes which ensures competitive control boards.

Flexible production which fits your needs

The board production, the automation production and the construction production are all placed in DK-6900 Skjern. The corporation between construction and production offers flexibility and eases our working processes.

Comprehensive test and final check of control boards

No control boards leave Orbital´s production before having passed the Factory Acceptance Test (FAT) in our own testcenter. FAT is performed by our experienced and skilled technicians who can also perform Site Acceptance Test (SAT) when needed.

Industriel control boards

Industriel control boards are used for both surveillance and controlling processes within the industrial sector. It may be as control boards for production machines or for processing plants. In all control boards there are different components. Electrical, and non-electrical. The electrical components are amongst others a main switch, switches for overvoltage, power supply, transformers, terminal clamps, PLC ( Programmable Logic Controller) and various communication units. The non-electrical components for instance consist of an assembly plate on which the control board is mounted, DIN- rails and wiring channels.

Cabinets for control boards

The control board itself is mounted inside a size fitted control cabinet adapted to the working climate. Orbital will fit a sealed climate system inside the cabinet if the installation climate requires so. This assists the control board to perform at its best at all times.

The control cabinet itself can have 1 – 3 doors and made of plastic, fibre glas, aluminium, stainless or lacquered steel. If you choose stainless steel, the cabinets will be a AISI 304 OR AISI 316 depending on the working climate. For coastal working climate, the AISI 316 is ideal due to its resistance towards salt.

The front of the control cabinet will have different buttons for the operators to work with for easy access. The buttons can be for an Emergency stop and Reset.

Vi bygger styretavler til mange forskellige brancher, maskiner og anlæg. Her er et par eksempler

OrbiSCADA monitoring for GAIA wind turbines

Control panel with HMI display for a CIP system

Retrofitting Danwin turbines in the USA

Retrofitting older wind turbines in Italy

Complete control systems for small wind turbines

All-in-one control systems for upgrading older wind turbines

Intelligent control and monitoring of stables

Control boards and operator panels for agriculture

Development and manufacturing of control systems for the fishing industry

Retrofit of wind turbines in Northern Ireland

Upgrading the iconic Tvind wind turbine

The TMC2 wind turbine controller and OrbiVib on the roof top of Castle House in London

Installation of 5.5 kW wind turbine at Nordisk Folkecenter

Control systems for off-grid wind turbines in Northern Ireland

Control boards and cabinets for vibration measurements

Development and manufacturing of cable sets for agriculture robotics

UL-approved control boards for the US and Canada

Inverters, TMC3 controllers and OrbiSCADA for Gaia wind turbines in the UK

SCADA monitoring for Vestas wind turbines

South Korean wind turbine manufacturer chooses Orbital in Skjern

OrbiSCADA for Vestas wind turbines

HMI panels for control cabinets

It makes sense to mount a HMI panel on the front of a control cabinet. Maintenance, service and quick access is important once the control board is active.

Orbital uses HMI panels from manufacturers such as Schneider and Siemens. Orbital uses the same manufacturer for the HMI panel and the PLC unit for our customers.

The user interface and selection of options on the HMI screen itself is programmed by Orbital according to the ISA-101 standard. Orbital will of course consider the overall user friendliness.

Production of high quality control boards

A successful production of control boards means the boards are built accordingly to applicable standards and that power components, cables and copper rails have the precise dimensions needed, and for safety to be on point. Correct registration of numberings and names of all components is also important so Orbital operators can service them with ease and troubleshoot in a minimum of time.

The temperature in the control cabinet is also a crucial factor. In some cases a heating unit or ventilation unit is necessary due to the working climate.The lay-out for the controlling board ensures enough room for ventilation, perhaps even cooling and foreseeable wiring.

The wiring in the control board will contain the as applicable correct colours to ease service and troubleshooting within the control board.

The PLC is central in every control board

The PLC is central in every control board . It is an industrial computer meant for harsh environment with heat, cold, dust and dampness. Its task is to monitor and control input and output.

It evaluates input and then changes output based on the algorithms it is programmed to read. PLC master many languages and Orbital use the conventional ones such as ladder logic, function block diagram, structured text and sequential function charts.

The PLC contains many different types of hardware, among others a CPU, memory and a programming unit. The PLC handles both digital and analogue input and output signals.

Your focal point

When you choose Orbital, you will have one personal focal point. You are welcome to telephone and e-mail your focal point when you need to. Orbital guarantees swift response. All communication from Orbital to you will always be from your personal focal point.